PolyPCW

Reduce, Reuse, Recycle

Post-consumer waste, or PCW, is material that has served its intended purpose as a consumer item, and has then been separated from other material, which is to be disposed of. Post-consumer waste has completed its life cycle as a consumer item and can now be recycled and reused.

PolyPCW is made from post-consumer waste that has already served its purpose. After collection and sorting, this material is reprocessed into high-quality polythene films – reducing the need for virgin plastic and lowering your carbon footprint.

Benefits of PolyPCW

Performance Maintained

PolyPCW films retain durability, strength and functionality for demanding industrial uses.

Eco-Friendly

PolyPCW contains 15-50% post-consumer recycled content, reducing environmental impact.

Tax Incentivized

Helps you comply with the UK Plastic Packaging Tax requiring 30% recycled content

Advanced Processing

PolyPCW uses multi-stage sorting and purification for consistent quality recycled batches.

Technologies & Specifications

Every batch is visually inspected and undergoes full physico-chemical analysis to ensure mechanical properties match application needs. Our strict quality protocols mean you get consistent film properties across orders.

Sourced from post-use waste streams including municipal, commercial, and industrial.

Post-Consumer Recycled

Can utilize a mix of PEHD, LDPE, transparent, coloured raw material, etc. based on application

Blended Material Streams

Samples from each recycled batch tested to ensure uniform thickness, clarity, strength

Lab Tested

Next day delivery on stock items within the UK when you place your order before 2pm (excludes some parts of Scotland and Ireland).

How we Create PolyPCW

Polythene UK have been working closely with Oxfordshire County Council to review possible ways of collecting household polythene.

After positive conversations with both the Council, and the local recycling centre, Dix Pit, it was decided that Polythene UK would provide a bin to collect the polythene. Since early March, each week the bin has been full to the brim and taken back to Polythene UK to recycle. At the end of March, a review meeting took place, all parties unanimously decided the pilot should be extended to include further centres.

Our sorting and recycling process includes up to four advanced techniques: optical, ballistic, densitometric, and infrared. These methods ensure the removal of contaminants such as PVC, paper, and other non-PE materials, producing a cleaner, more reliable material for new production.

Based on the application, we can create different blends using transparent or coloured LDPE, HDPE, and other suitable raw materials. Each batch is tested for consistency and performance – from basic packaging to high-demand industrial films

We turn this...

Into this...

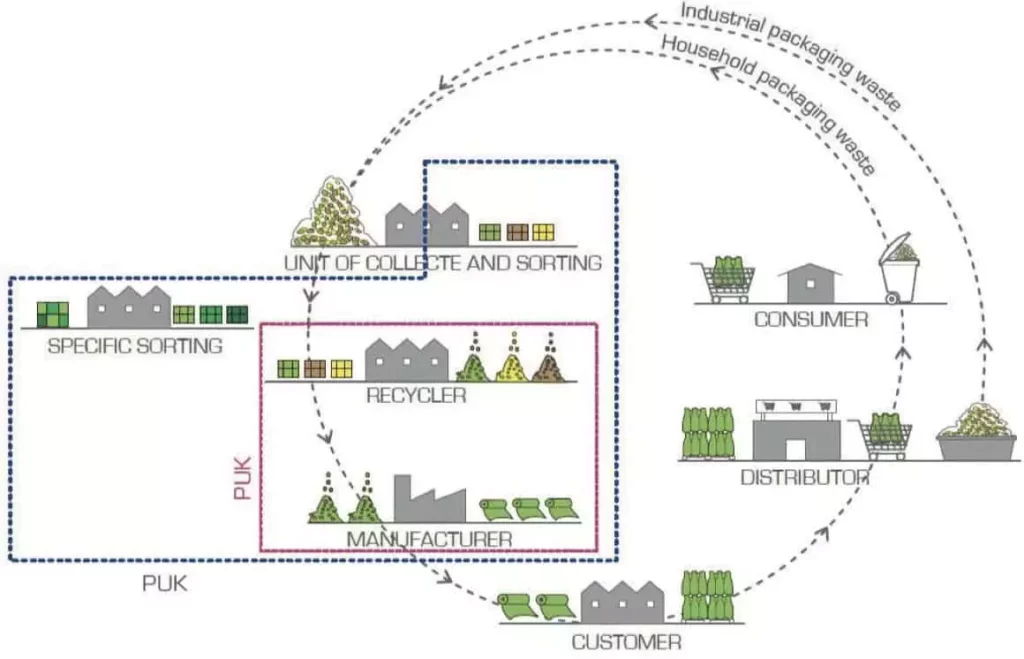

How it works

Once we receive the waste material there are 4 possible sorting methods:

• Optical sorting

• Ballistic sorting

• Densitometric sorting

• Infrared sorting.

• The more refined the sorting method, the more raw material is considered clean (free of all interfering substances: PES, PP, PVC, paper, etc.) and therefore good.

• Depending on the quality of the material we receive, we can choose a number of sorting methods in order to purify the final mixture.

• The ‘clean’ waste is then crushed, washed and transformed into granules. • The recycled PCW can then be put into the middle layer of a 3 or 5 layer co-extruded film, which is then turned into a polythene bag or film.

We need your waste polythene

We “need” more waste polythene to recycle, so we have launched

a new free mobile national waste polythene collection service. Our van

is on the road with a polythene baling/compactor fitted inside which

will enable us to help you recycle your waste polythene without the

expense of buying or hiring a polythene compactor yourself. This will

save you a £3,000 initial cost, not to mention the ongoing maintenance

charges. Our service is free of charge and hassle free too!

How can we offer this I hear you ask and is it green to add another vehicle on our roads?

We have of course carefully considered our plan, as we keep our green credentials at the heart of everything we do.

Our van will be collecting nationally when we have visits to that part of the country on our normal day to day supplier/delivery visits, each trip will have a minimum of two purposes.

Once we have collected your waste film and recycled it, Polythene UK would aim to offer you that recycled material back as the 30% post-consumer waste in your future orders. Polythene UK is creating the perfect closed loop/circular

economy solution for polythene packaging, supplies and recycling service.

Our full integration — from collection to recycling to re-supply — gives you a secure and traceable source of recycled material. You know exactly where your polythene comes from and where it goes.

Hopefully if we have solved the commercial issue of collecting the waste polythene we will always be able to offer you a cheaper end polythene film/ bag/cover because the recycled waste polythene is far cheaper than the virgin grade oil by-product currently being used. Polythene has a particularly poor CO2 effect on the planet – UNLESS it’s being recycled then it’s transformed to one of the most positive packaging products on the planet. In addition to this, we can make any polythene you use by mixing the recycled polymer with our plant-based solution Polyair™, this means the new polythene supplied is in fact PAS2050 certified.

Frequently Asked Questions

Why do we need to know about PCW?

At Budget 2018, the government announced that from April 2022 it would introduce a new tax on the production and import of plastic packaging with less than 30% recycled content.

Although details of the tax have yet to be confirmed; the tax will be set at a rate that provides a clear economic incentive for businesses to use recycled material in the production of plastic packaging.

Thanks to the efforts of Polythene UK and the combined collaboration of various sectors, we can now produce films and tubes suitable for the industrial sector that are made from after-use recycled material.

This has required a complete and modelled integration from the waste collection to its conversion into a new product. But why did we integrate ourselves? In order to have the control of our waste and to give security to our customers in the supply’s sustainability and in the batch’s reliability and traceability.

Polythene UK work with the most sophisticated PCW sorting plant in Europe and currently process 20,000 tonnes of PCW plastic a year. Using the latest washing and optical sorting technology they can produce better quality regenerated polymer.

What are the advantages of using PCW?

- Ensures high quality and consistent recycled plastic material

- Provides a controlled supply source of regenerated raw material

- Allows full traceability back to the sorting facility

- Has less environmental impact than using 100% new plastic

What types of PCW does Polythene UK use?

Polythene UK uses PCW from domestic, agricultural, and industrial sources. This can include both transparent and colored plastics. Different mixtures are made with various types of polyethylene plastic, tailored to customer requirements. Products range from low, mid to high quality PCW content.

Can you request samples of Polythene UK products using PCW?

Yes, we offer free sample products featuring its post-consumer recycled polythene upon request. Minimum order quantities apply. Contact Polythene UK to request samples or get a quote.

In partnership with

Request a free sample

You can request a free sample of any of our products. Enter your details below and a member of the team will get back to you. Please note there is a minimum order quantity.