Machine Stretch Film

Secure items and protect your products with our high-performance machine stretch film. Our machine pallet wrap arrives pre-stretched for greater efficiency and reduced costs, while our use of fold-over edges at the top and bottom of the roll ensures the same high strength and long-lasting protection.

Our machine grade stretch film helps to secure palletised loads for transport through the easy application with all stretch film machines. By providing a strong tear-resistant layer to your products, it prevents the movement or damage to your palletised loads during transport and storage.

Polythene UK, as machine stretch wrap suppliers, stocks a full range of machine stretch wrap film to suit all standard and power stretch applications, with the ability to produce any combinations of thickness and PPS percentage on the market.

Our Range of Machine Stretch Wrap Film

150% PPS as Standard

Typically used on a standard/traditional core break pallet turntable wrapper, your machine does not pro-actively stretch your film.

In this instance we would recommend a free trial of our thinner 7 layer 250% PPS machine film which guarantees a minimum cost saving of 26% from your current supplier.

Power Pre Stretch Film

Typically used on a semi-automatic pallet wrapper, your machine is pro-actively pre-stretching the film before it is applied to the pallet. The gearing/brake system will stretch the film from 200% PPS up to 400% PPS depending on the machine capabilities and settings. In all instances, our 7, 9 or 33 layer films will enable you to downgauge (optimize) by a minimum of 26%.

Fold Over Edge Pre Stretched

Pre-stretch film technology was invented to maximise optimisation, typically taking a film from 17mu down to 6mu, where we can also fold over the edges of the film so it remains twice as thick at the critical breaking point.

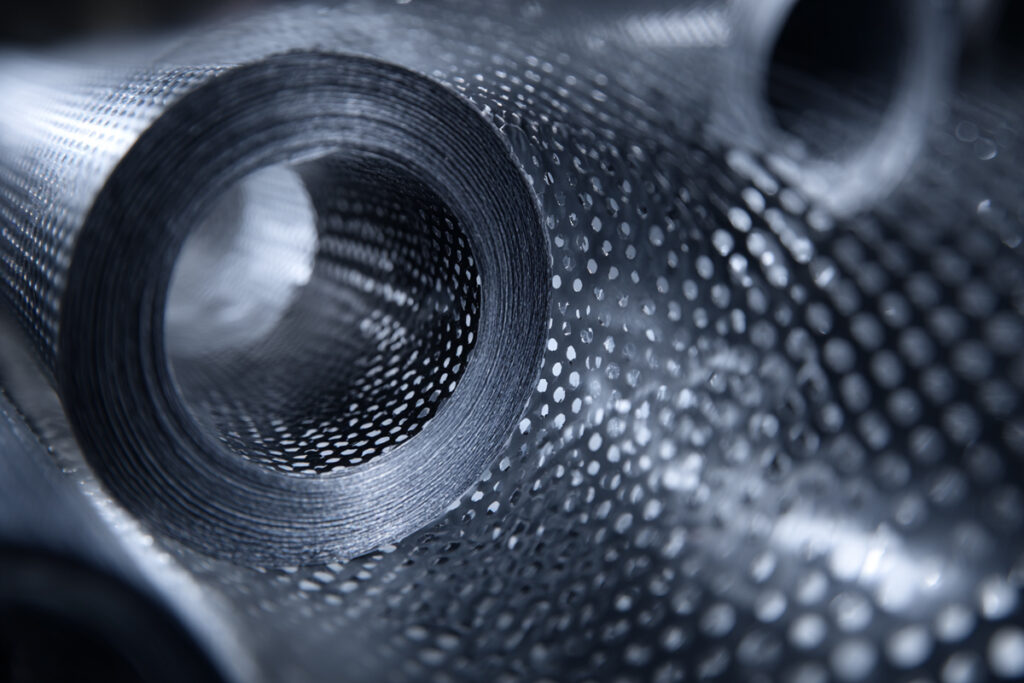

Macro and Micro Perf Machine Film

Designed for wrapping specialized products that require ventilation or specific wrapping techniques.

Printed Machine Film

Enhance your brand visibility with our custom-printed machine film, available in a variety of sizes and designs.

Machine Stretch Film Specifications and Technologies

| Product | Thickness | Dimension | Weight | Machine stretch film | 50mµ | W 700 x L 2000 mm | Roll weight 16.5 kg |

|---|---|---|---|

| Machine stretch film | 50mµ | W 500 x L 2000 mm | Roll weight 17.5 kg |

| Machine stretch film | 50mµ | W 800 x L 2000 mm | Roll weight 16.5 kg |

Print options: printed in 1, 2 or 3 colours

Recyclability: fully recyclable

Degradation: Oxo-degradable

Next day delivery on stock items within the UK when you place your order before 2pm (excludes some parts of Scotland and Ireland).

Polythene UK launches first ever opaque blue Machine Film:

Polythene UK – first to launch “opaque blue” 250% cast PPS machine film – BRC certified and 100% LDPE04 recyclable

Frequently Asked Questions

What are the benefits of using machine stretch film?

Machine stretch film is an effective way to package and secure pallet loads during transport and storage. It offers load stability by wrapping tightly around the pallet and preventing shifting or damage, reducing the need for repacking or replacing goods. It is cost-effective, lightweight, and provides protection against moisture and contaminants, preserving product quality.

Its application is quick and efficient using a stretch wrapping machine, which saves time and labour costs. The film is versatile, with different widths, lengths, and thicknesses available to suit different load sizes and weights. Overall, using machine stretch film can help improve load stability, reduce packaging costs, protect products, increase efficiency, and provide versatility for a wide range of packaging applications.

Is machine stretch film recyclable?

Our machine stretch wrap film is fully recyclable and Oxo-degradable. We offer sustainable machine stretch film which can help reduce the environmental impact of the material and promote a circular economy.

What types of machines can be used for machine stretch film?

Some common types of machines used for machine stretch film include:

- Turntable stretch wrappers have a rotating platform to spin the pallet and apply stretch film using a vertically-mounted carriage.

- Rotary arm stretch wrappers have a rotating arm that moves around the stationary pallet to apply the stretch film.

- Orbital stretch wrappers wrap the stretch film by rotating the film carriage in a horizontal circle around the stationary pallet.

- Ring stretch wrappers have a ring-shaped structure that moves up and down the pallet while wrapping the stretch film.

- Horizontal stretch wrappers apply stretch film to the pallet as it moves through a horizontal wrapping station.

How does machine stretch film help with pallet stability?

By providing a secure and stable wrapping around the products on a pallet, machine stretch film helps with load containment (preventing products from shifting or sliding during transport), delivers enhanced stacking ability (palletised products can be safely and efficiently stacked on top of one another, providing an added layer of stability), improves weight distribution (preventing heavier items from crushing or damaging lighter ones), and protects your pallet and products from moisture and dust.

Request a free sample

You can request a free sample of any of our products. Enter your details below and a member of the team will get back to you. Please note there is a minimum order quantity.