This month I want to look at the benefits of Polyolefin when compared to PVC in shrink wrapping applications.

This month I want to look at the benefits of Polyolefin when compared to PVC in shrink wrapping applications.

The question is: Should you still be buying PVC or changing to Polyolefin film? What is the difference between the two? Is one better than the other?

The first thing to do when looking for the right packaging material is analyse what you are packaging. This can affect the type of shrink film you use – consideration must be given to whether or not the product is edible, if multiple products need to be packaged together, if there are any sharp corners and whether or not the shrink wrap machine will be used indoors.

Historically, PVC film has been very popular, it was inexpensive and widely available. It has been widely used for CD/DVD packaging and wrapping boxes, software and other non-edible products. However, PVC film is brittle and not good for use with bundling multiple products, nor is it safe for use with food products. The other downside is that PVC production lines create odour and smoke as the film deposits on the sealing equipment and carbon build up on the sealing tools over time. Although PVC film has long been the film of choice, Polyolefin film has been growing in popularity over the past few years and is now almost as common as PVC shrink film.

Benefits of Polyolefin film

- Environmentally friendly – easily recyclable

- Lower cost per foot than PVC

- It doesn’t become brittle and yellow with age

- It’s more pliable than PVC film and does not tear easily

- As a multi layer film the finished packs are very strong and presentable

- It’s puncture resistant and tough

- It gives better results where clarity and shelf life are important considerations

- It gives better results when bundling multiple products

- It’s approved for direct food contact

- It doesn’t break down during the heat-sealing phase of packaging

- It’s clean to use – less machine maintenance and a cleaner, higher quality overall appearance

- No need to use Teflon curtaining over sealing wires

- No smell or smoke when sealing – fine for use indoors

- Most shrink wrap machines are capable of using both PVC and Polyolefin film. The heat required to shrink both types of film is about the same – so swapping to Polyolefin is easy.

The good news

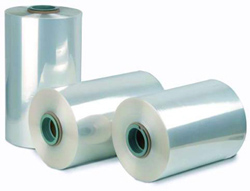

Polythene UK currently stock a superb quality double-oriented thermoshrinkable polyolefin film. This is a multi-purpose film with exceptional tensile strength, tear resistance, high shrinkage performance, good optics and excellent hot slip properties.

Polyolefin gives outstanding results on manual and automatic high-speed machines. It is available in 12.5–25 micron, either centrefolded or single wound and comes on rolls of various lengths.

Its high transparency gives excellent exposure of the packed product making it an ideal solution for introductory and promotional packages. Besides the extra optical features, polyolefin film gives high yield that reduces the packing costs, keeping the end product price-competitive.

Environmental benefits remain important – polyolefin film is easily recycled and no harmful vapours are emitted during heat sealing.

Its technical parameters mean that it can be used on both manually operated and fully automated machines. There is no machine corrosion which extends machine life and results in lower maintenance costs. These advantages make the polyolefin film a good alternative to PVC film.

Contact our Sales Team on 0845 643 1601* to see how changing to Polyolefin will benefit your business. Alternatively, you can email us on our Contact page.